Which 3D printing technology is used to produce medications?

3D printing represents a promising technology for the manufacturing of reliable and secure personalized medications. Through 3D printing, it is possible to customize treatments to meet the specific needs of each patient. Additionally, this technology improves patient compliance by modifying the shape of medications. In the pharmaceutical industry, 3D printing accelerates drug development by providing rapid prototyping capabilities. Also, pharmaceutical 3D printing makes it possible to carry out tests during the development process. There are several 3D printing technologies available in the market, each with its own advantages and disadvantages when it comes to medication production.

Each technology has its own application

Do you need to produce personalized medications or accelerate the development of a new drug? Each 3D printing technology will adapt to different needs. MB Therapeutics, a pioneer in pharmaceutical 3D printing, offers a simple way to explore the various possibilities available today.

3D printing FFF (Fused Filament Fabrication)

FFF or FDM (Fused Deposition Modeling) printing technology is a common 3D printing method that uses melted thermoplastic filament to build an object layer by layer. This technology is particularly well-suited for the production of personalized medications that are not temperature-sensitive.

The production of the filament requires a high level of expertise in extrusion technology and a 3D printing head specifically designed for pharmaceutical filaments.

FFF technology is affordable, user-friendly, and secure as it involves handling solid materials, which limits the risk of contamination.

That is why MB Therapeutics is integrating pharmaceutical filament technology into its MED-U Modular pharmaceutical printer.

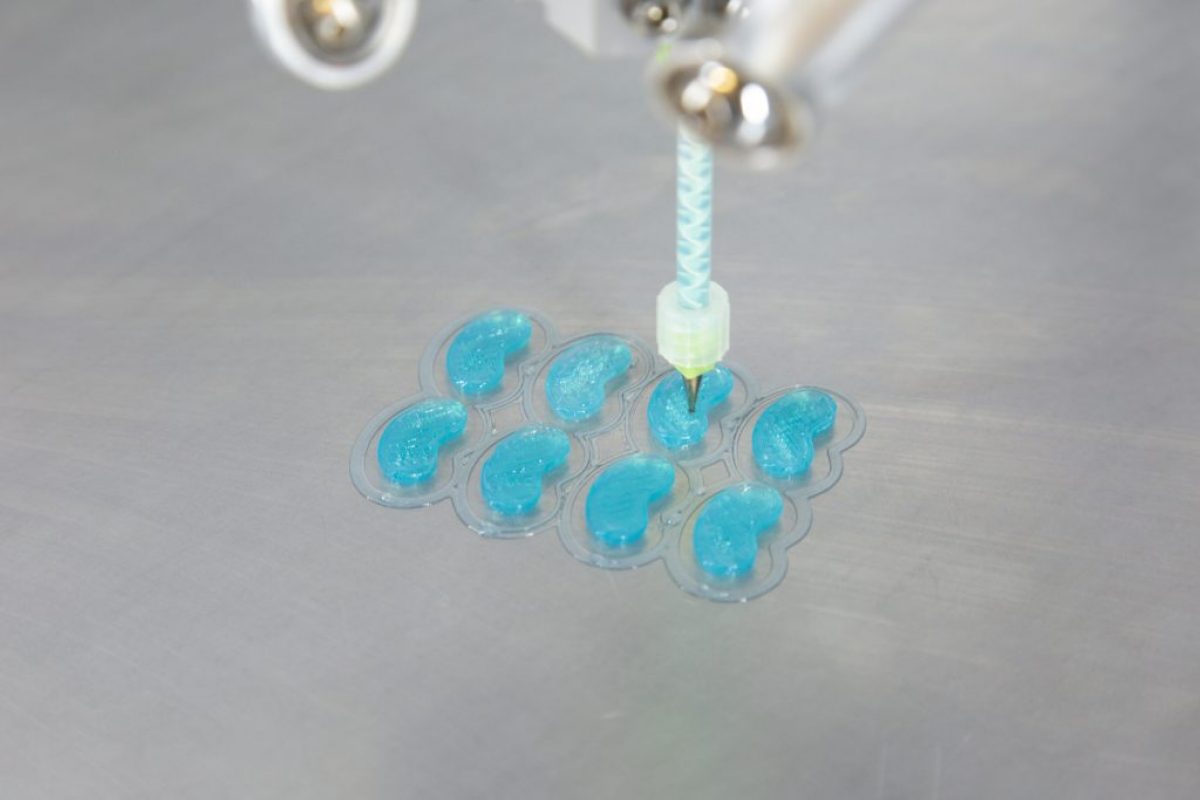

3D printing of gels/pastes

The gel printing technology uses a gel or paste that is deposited layer by layer to create a solid object. This technology enables rapid prototyping and formulation development. If your active ingredient is not water-sensitive, this technology is particularly suitable for the production of personalized medications. That is why MB Therapeutics has integrated this technology into the MED-U Modular.

Source: MB Therapeutics

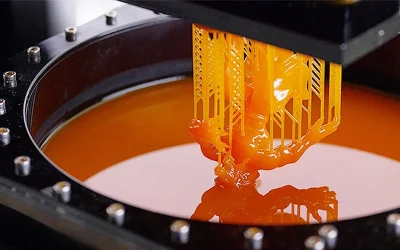

Source: 3DNative

SLA 3D printing (Stereolithography)

SLA technology (Stereolithography) uses a liquid resin that is cured using a laser to form a solid object layer by layer. In the pharmaceutical field, only a few excipients can be in resin form, and the presence of monomer residues in the resin can pose a health risk, thus requiring careful control.

SLS 3D printing (Selective Laser Sintering)

SLS technology (Selective Laser Sintering) uses a polymer powder that is fused layer by layer using a laser to form a solid object. A wide variety of active pharmaceutical ingredients (APIs) are sensitive to the laser, and the use of powder makes it challenging for daily use.

Text content

Material extrusion 3D printing technologies (gels and FFF) are a widely adopted 3D printing technologies that can be used in personalized medicine. These processes enable the creation of medications with specific dosages tailored to individual patient needs. Simple, affordable, and widely accessible, these 3D printing technique are well-suited for personalized medicine applications, which MB Therapeutics currently offers with its MED-U Modular.