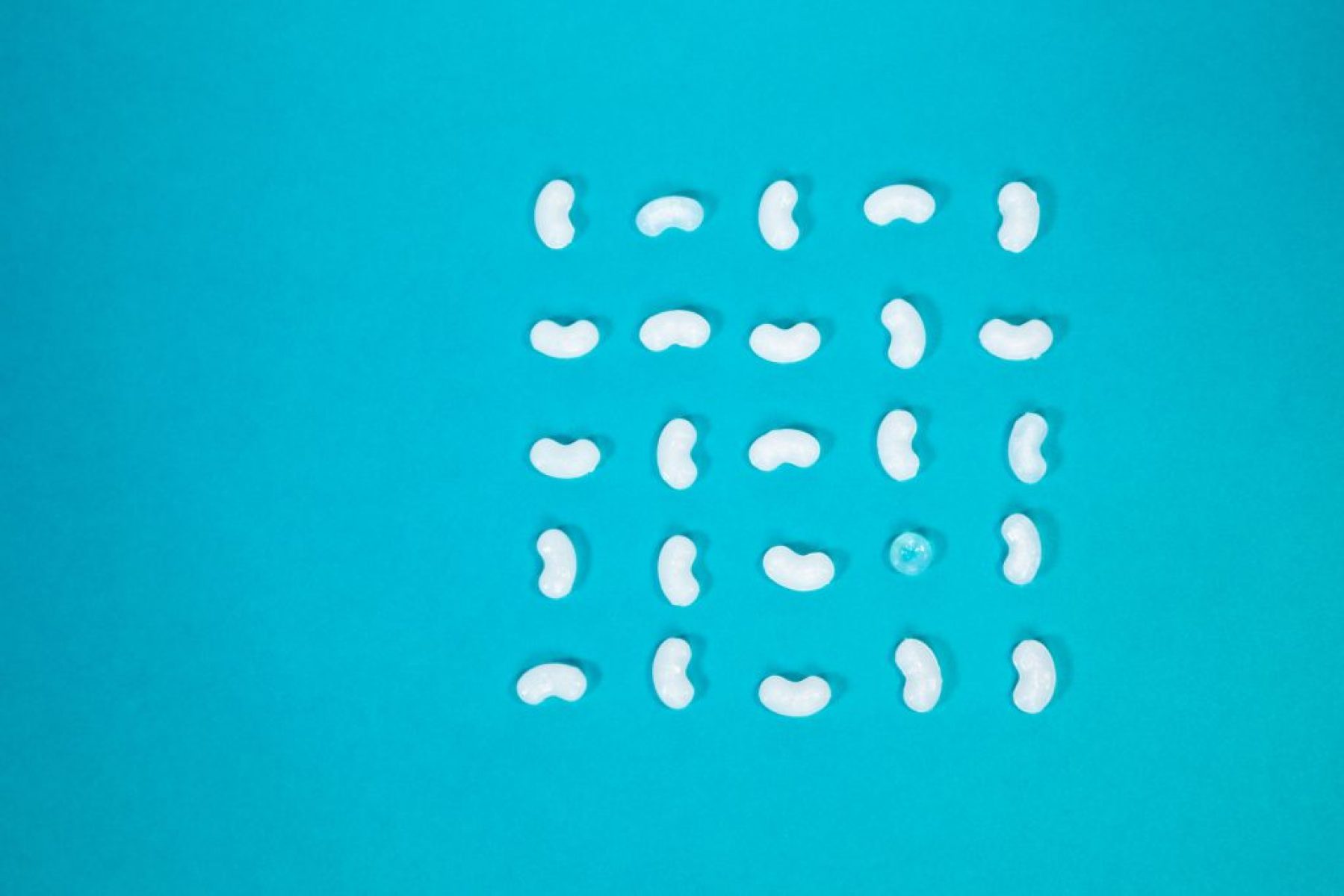

3D printing in the pharmaceutical industry

MB Therapeutics flexible technologies enables fast development of oral galenical forms.

A more agile development approach

Save time and resources in pharmaceutical R&D

- Achieve more flexible and adaptable clinical trials

- Improve time to market

- No need for formulation redevelopment between Phase 1 and 2A

- Same formulation for Single Ascending Dose (SAD) and Multiple Ascending Dose (MAD) studies

- Reduce waste by printing medications on demand

- And much more advantages here

Is my molecule printable?

Let’s discuss its printability!

By discussing its physicochemical properties, we can provide you with an evaluation of its printability and determine which pharmaceutical 3D printing technology is best suited for it.